Forged carbon steel pipe fittings/forged steel pipe fitting/

Basic Info

Model No.: TP304 ,TP321 , TP316,TP304L, TP310S ,TP347,S31803. S2205,etc,TP304/316

Product Description

Stainless Steel: ASTM A 182

Grade: F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H

Carbon Steel: ASTM A 105, A187,( 54686690,IBR & NON IBR)

alloy Steel: ASTM A 182, Grade F1, F11, F22, F5, F9, F91 (IBR & NON IBR)

Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy 904

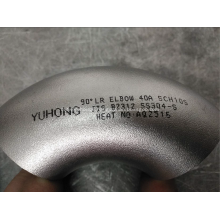

TYPES : Elbow, Tee, Union, Cross, Coupling, Cap, Bushing, Plug, Swage Nipple, Welding Boss, Hexagon Nipple, Barrel Nipple, Welding Nipple, Parraler Nipple, Street Elbow, Hexagon Nut, Hose Nipple, Bend, Adapter, Insert, Weldolet, Elbowlet, Sockolet, Thredolet, Nipolet, Letrolet, etc.

Size : 1/8"NB TO 4"NB (Socketweld & Threaded)

Size : 1/2"NB TO 4"NB IN

Class : 3000 LBS, 6000 LBS, 9000 LBS

Type : Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT

Form : Socket, Half Socket, Full Socket, Reducing Socket, & Customized Socket.

Nickel Alloy Socket :

Standard:

• ASTM / ASME SB 564 / 160 / 472

• UNS 2200 (NICKEL 200 Socket)

• UNS 4400 (MONEL 400 Socket)

• UNS 8825 (INCONEL 825 Socket)

• UNS 6601 (INCONEL 601 Socket)

• UNS 10276 (HASTELLOY C 276 Socket)

• UNS 2201 (NICKEL 201 Socket )

• UNS 8020 (ALLOY 20 Socket)

• UNS 6600 (INCONEL 600 Socket )

• UNS 6625 (INCONEL 625 Socket )

Copper Alloy Forged Fittings :

ASTM / ASME SB 61 / 62 / 151 / 152.

C 70600 (CU -NI- 90/10) – Cupro Nickel Forged Fittings

C 71500 (CU -NI- 70/30) – Copper Nickel Forged Fittings

UNS NO. C 92200, UNS NO. C 83600, UNS NO. UNS NO C 10100,

C 10200, C 10300, C 10800, C 12000, C 12200

Duplex Steel Forged Fittings

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Stainless Steel Forged Fittings – SS Forged Fittings

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Alloy Steel Forged Fittings - AS Forged Fittings

ASTM / ASME A/SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel Forged Fittings - CS Forged Fittings

ASTMA 105/A694/ Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel Forged Fittings - LTCS Forged Fittings

A350 LF3/A350 LF2

Value Added Services :

• Hot Dip Galvanizing

• Electro polish

Test Certificate :

Mill Test Certificate as per EN 10204 / 3.1B

fittings general:

A Socket Weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or Flange. In contrast to buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller.

To join pipe to Valves and fittings or to other sections of pipe, fillet-type seal welds be used. Socket-welded Joints construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations.

Fatigue resistance is lower than that in butt-welded construction due to the use of fillet welds and abrupt fitting geometry, but it is still better than that of most mechanical joining methods.

Some details of Weld fittings:

SW Fittings are family of high pressure fittings are used in various industrial processes.

- They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

- They are used only in conjunction with ASME Pipe and are available in the same size range.

- They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

- They are are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical compositions, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

- They are available in three pressure ratings: 3000lbs, 6000lbs and 9000lbs.

-

TYPES OF SOCKET WELD FITTINGS BY CLASS, SIZE AND WALL THICKNESS

Plugs and Bushings are not identified. They may be used up through Class 6000 NPSDescription Class Designation 3000 6000 9000 Elbows 45 and 90 degrees,

Tees, Crosses, Couplings,

Half-Couplings,

End or Pipe Caps½ - 4 ½ - 2 ½ - 2 ½ - 4 ½ - 2 ½ - 2 ½ - 4 ½ - 2 ½ - 2 Pipe Size

by Wall ThicknessSCH 80 & XS SCH 160 XXS Advantages of fittings

Advantages

- The pipe need not be beveled for weld preparation.

- Temporary tack welding is no needed for alignment, because in principle the fitting ensures proper alignment.

- The weld metal can not penetrate into the bore of the pipe.

- They can be used in place of threaded fittings, so the risk of leakage is much smaller.

- Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP), or liquid penetrant (PT) examination methods.

- Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

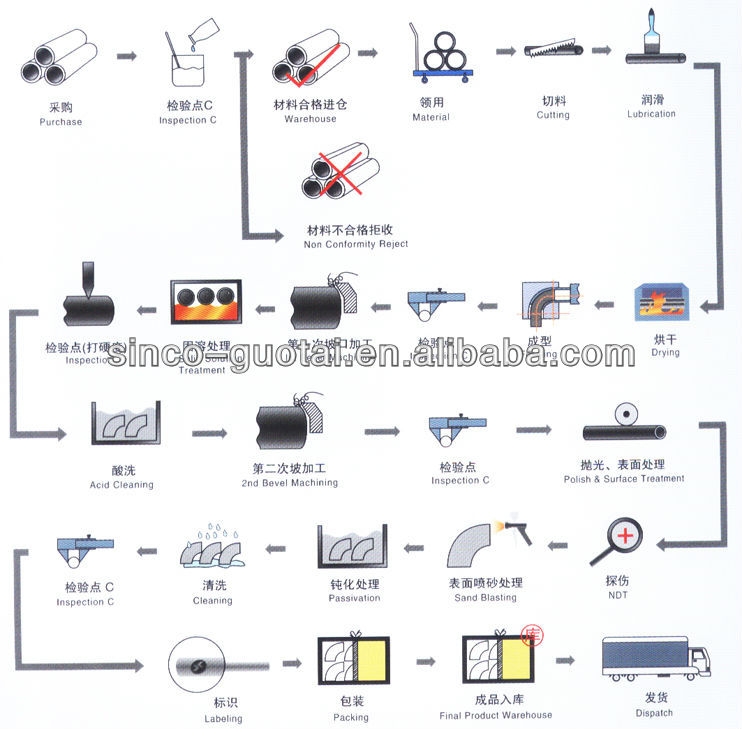

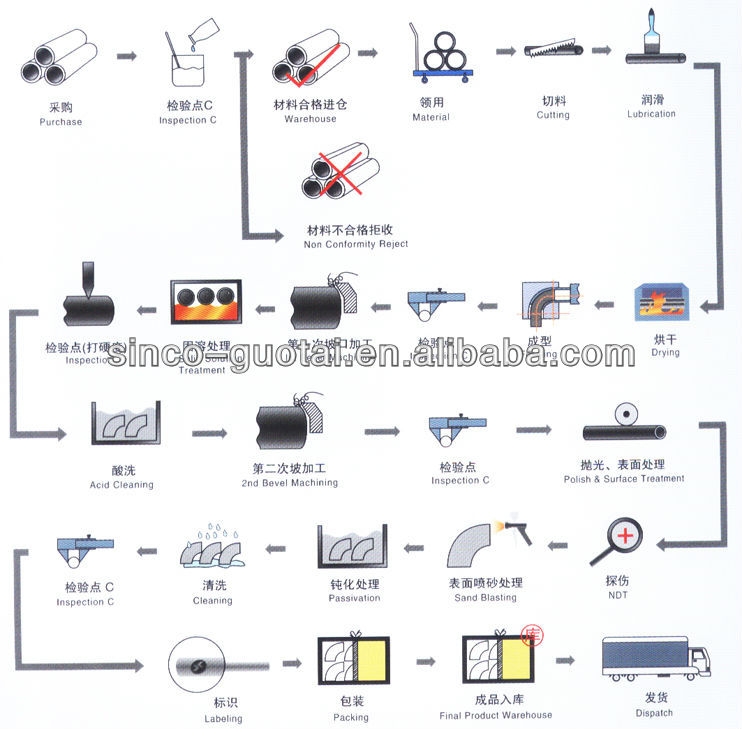

- Production Facility

Products Testing

Package

PRODUCTION WORKFLOW

Certificates

Product Categories : Butt Welded Pipe Fitting

Premium Related Products